Position and Force Sensors

Bokam designs and manufactures force sensors and condition monitoring systems for the industrial, military, medical, maritime, and aerospace verticals. Any organization can trust our rugged sensors to provide accurate results for years to come.

Bokam offers a wide range of force and position sensors that are based on our unique solid state force measurement technologies. The product line offers multi-axis measurement that can be configured to measure both force and position depending on configuration of integration hardware. The sensors are designed to work with a wider range of Bokam electronics that are programmable and provide for in use calibration and re-setting. The Bokam force and position sensors also come in fully submersible configurations that can be used for subsea condition monitoring, force measurement, and position measurement applications.

Key Features and Advantages:

- Solid state sensors with extreme survivability and life expectancy in the billions of life cycles

- Highly repeatable and stable sensors can be used in condition monitoring and OEM systems without maintenance or repair requirements over the life of the system

- Fully submersible product lines available

- Multi-axis sensors available to measure X, Y, Z, and rotation force application

- Multi-channel devices available for redundancy of measurement

- Stand-alone or integrated electronics provide multiple output types to fit virtually any system interface requirements – including USB, Ethernet, CAN, and analog outputs

- Custom configurations and customization of sensor interfaces available on request

Order Your Condition Monitoring Systems

Bokam’s condition monitoring systems offer top-rate reliability and survivability for any application or environment. If you need better force sensors, position sensors, and more, try one of our products below.

Miniature Neptune Input Device

- Industries only fully submersible, non-audible, non-magnetic, fully submersible man-machine interface input device and force and position sensor

- Non-Audible functionally

- Non-Magnetic

- No moving or rubbing parts to ware out during operation

- Performance or survivability not affected by dive depths

- Performance or survivability not affected by exposure to sea water

- Highly rugged

- No catastrophic failure mode – damage does not cause leakage of system and in most cases is reversible

- High accuracy and linearity

- Inherently temperature stable

- High overpressure and burst pressure capability

- Various fitting and interface options available

- Various force and sensitivity ranges are available in the same basic package

- Stand-alone electronics provide various output including USB (cursor control, game control and switching), CAN (proportional and non-proportional), Analog and Switching

- Variations in Installation methods can be used for wide range of applications:

- HMI - Cursor control, Game control, Digital output and switching

- Force sensing and reporting

- Linear and rotational position measurement and reporting (contact factory for installation guidelines

Sealed Position / Force Measurement Sensor

Construction:

- Solid-state welded (hermetically sealed) force or position sensor

- Solid-state stainless-steel construction

- Internal electronics can be provided a wide range of outputs

- Package provides up to four axes (8 directions) of control

- Fully Potted Zero volume explosion proof packaging

- Force or Position proportional output

Advantages:

- Solid-state input devices and sensors without moving or rubbing parts for ultimate life, survivability, and performance

- Meets/exceeds Automotive EMI/RFI susceptibility requirements and MSHA certification standards

- Increased reliability and extreme life capacity

- Meets the most stringent environmental requirements

- Programmable microprocessor-based electronics

Options:

- Fully welded, stainless steel input device with force proportional inputs

- Potted and sealed construction

- USB or Analog output

- Output can be calibrated to meet specific force or travel requirements

- Industrial shielded and mining approved cable options available

- Rear exit or top exit cable options

- Additional S-Spring package to measure position and travel instead of force

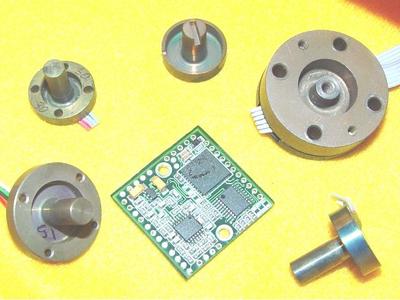

US-Series Solid-State Multi-Axis Input Devices

- Award winning Solid-State Sensor technology

- Lowest profile, high rel. input device available on the market

- Miniature, Multi-axis - proportional devices

- Extreme life with 10 billion life cycles min.

- Immune to contamination, debris, moisture, and temperature extremes

- Works with a wide range of signal conditioning electronic to meet various applications

- Can be packaged both in force proportional and position proportional applications

Functions:

- Universal sensor works with various standard Bokam electronics as both force sensor and input device

- Operation can range from cursor control to game control or combined with converters for various serial or bus interfaces including RS232/RS485 and CAN bus converters

- Uses and Functions based on programming of electronics and range

Options:

- Various post height and sensitivity options available

- Works with either position proportional or force proportional cap/finger interfaces

- Integrated proportional and non-proportional output profiles available with programmable dead bands.

- Programmable Output Options:

- Proportional man-machine interface controls

- Switching and digital controls

- Force sensing

Your organization is only one phone call away from obtaining the sensory devices you need. Contact Bokam now to order our condition monitoring systems.